Description

TAS Safety Valve –

For use with back boiler and “un-vented” hot water

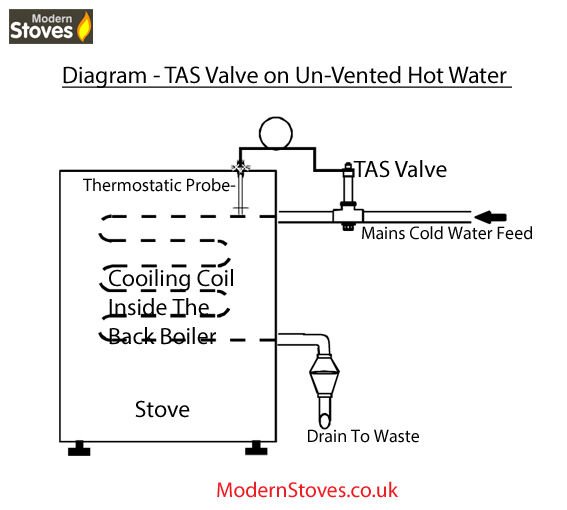

The TAS Valve is a thermostatic valve, which is designed to be used with multi-fuel back boiler stoves that are equipped with a cooling coil / heat exchanger within the back boiler.

Some back boiler stoves are equipped with a separate cooling coil which runs inside the back boiler of the stove. The cooling coil can be used to reduce the temperature of the water within the back boiler by allowing a flush of cold water to run through the cooling coil, thus reducing the temperature of the water within the back boiler. The TAS thermostatic valve is a safe an effective way of controlling the temperature and pressure of water within a back boiler stove.

The TAS safety valve is designed to control the flow of the cold water through the cooling coil. The TAS valve is equipped with temperature sensor / probe which is connected to the body of the TAS valve by a 1300mm thermo-couple cable wire. The temperature probe should be located on the back of the boiler or on the flow pipe work. The TAS valve is then connected in line on a mains cold water feed, which is plumbed to the cooling coil within the back boiler of the stove. The TAS valve then monitors the temperature of the water in the back boiler and automatically opens to release a flush of cold water in to the back boiler when the water temperature within the boiler exceeds 97 degrees. As the cold water flows through the cooling coil in the back boiler, the cold water absorbs the heat and thus cools the surrounding main body of water.

The TAS safety valve does not require any electrical connection and is primarily designed to be used where an un-controlled heat source, such as a multi-fuel stove, is used to heat hot water in a sealed / un-vented or vented hot water system. A multi-fuel stove is classed as an uncontrollable heat source because it cannot be turned on, or off, like a gas or oil fired boiler and therefore the stove has the potential to heat the water in an un-controlled fashion. In an un-vented hot water system this can lead to excessive pressure, which if left un-controlled can cause damage to the plumbing and the stove. In a vented hot water system the prolonged boiling of the water

In order to utilise the TAS safety valve the stove requires a mains cold water feed to be piped to the back boiler within the stove and also a further drain off pipe to be piped from the back boiler to an outside drain for the purpose of expelling the mains cold water.

The TAS valve is designed to be installed within 1 metre of the stove, and is fitted in-line, on a mains cold water feed (15mm pipe). The TAS valve is equipped with a temperature probe which is attached from the TAS valve to the stove by a thermo-couple wire which measures 1300mm in length. The Temperature probe monitors the temperature of the hot water within the back boiler and when the water within the back boiler reaches 97 degrees, the TAS safety valve will automatically open to release a flush of cold water in to the cooling coil within the back boiler.

NOTE, the cold water that is released by the TAS valve should not contaminate, or come in to contact with the main body of water within the back boiler, since it flows through a separate cooling coil within the back boiler. Once the cold water has flowed through the back boiler cooling coil it is discharged to an outside drain.

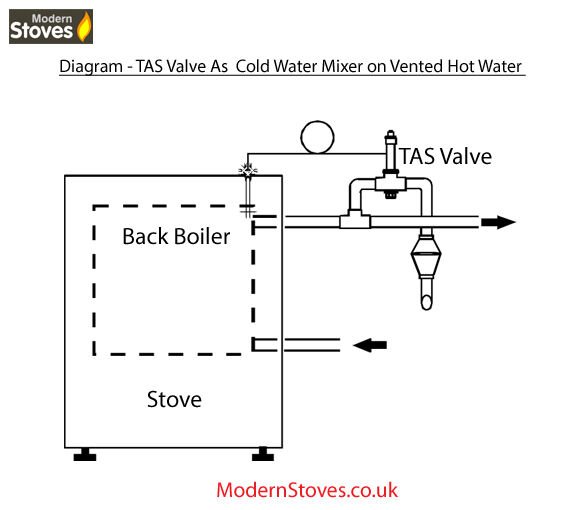

Open Vented Hot Water: The TAS safety valve can be used in conjunction with an open vented hot water system, where there is a chance of the water boiling or overheating, and where there is no heat dump present. Typically this can cause a symptom known as kettling, where the water can be heard boiling within the back boiler. In this scenario the TAS valve can be used to introduce mains cold water in to the flow pipe from the back boiler, in order to blend cold water with the hot water. The additional water will then discharge through the overflow on the header tank.

Back Boiler Stoves Suitable For Use With Un-Vented Hot Water: We sell a range of back boiler stoves and cookers that are designed to be used with un-vented hot water. They are manufactured to operate at 2 bar working pressure and are equipped with a cooling coil that runs within the main back boiler. The stoves models are as follows: Condor Cooker BO – Apollo BO – Marinela BO – iStove Lux BO – Titan with back boiler – Mercury Back Boiler – Mercury Hex Back Boiler- Magenta BO.

Some of the stoves with back boiler in our product range have an automatic air vent which also monitors the temperature of the water within the back boiler, and when the water reaches 96 degrees, the primary air vent will automatically close, thus starving the fire of air and reducing the heat output.

Features:

The thermal safety is valve required for temperature protection in closed hot water heating systems up to a maximum 93 KW = 80 000 kcal / h, in conjunction with a multi-fuel stove with back boiler..

The TAS safety valve is an independent valve, which opens when the water temperature within the back boiler of the stove reaches 97 ° C.

The internal sealing piston / valve is driven centrally thus preventing the risk of jamming / stalling.

No housing parts are made of plastic, and are therefore resistance to high temperatures.

Suitable for temperatures of up to 125 ° C

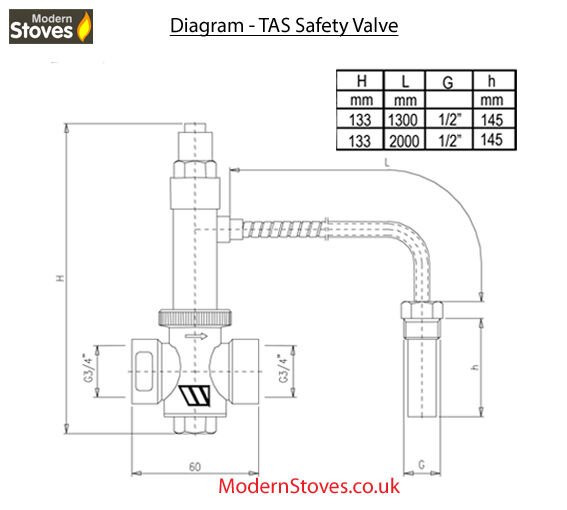

Specifications

Solid brass housing

Maximum operating pressure 10 bar

Temperature response point 97 ° C

Maximum operating temperature is 110 ° C

Maximum capacity 6.5 m

Thermo-couple cable length 1300mm

Pipe connection size: 3/4″ (three quarter inch)

Thermostatic dip tube with sensor for insertion / attachment to the back boiler

Back Boiler Stoves Suitable For Use With Un-Vented Hot Water: We sell a range of back boiler stoves and cookers that are designed to be used with un-vented hot water. They are manufactured to operate at 2 bar working pressure and are equipped with a cooling coil that runs within the main back boiler. The stoves models are as follows: Condor Cooker BO – Apollo BO – Marinela BO – iStove Lux BO – Titan with back boiler – Mercury Back Boiler – Mercury Hex Back Boiler- Magenta BO.

Some of the stoves with back boiler in our product range have an automatic air vent which also monitors the temperature of the water within the back boiler, and when the water reaches 96 degrees, the primary air vent will automatically close, thus starving the fire of air and reducing the heat output.

PLEASE NOTE: PRESSURISED HOT WATER CAN BE DANGEROUS.

NEVER USE SOLDER JOINTS ON PLUMBING PIPEWORK WITHIN 3 METRES OF A STOVE. YOU MUST USE BRASS COMPRESSION FITTINGS FOR ANY JOINTS OR FITTINGS.

ALWAYS FIT AT LEAST ONE EXPANSION SAFETY VESSEL TO EACH CLOSED LOOP OF PIPEWORK (Min 25 LTR)

ALWAYS FIT AT LEAST 2 SAFETY BLOW OFF VALVES TO EACH CLOSED LOOP OF PIPEWORK, PLEASE DO NOT BE TEMPTED TO ONLY FIT 1, AS THE SECOND SHOULD BE FITTED AS A BACKUP. NB. IN AREAS WHERE THE MAINS COLD WATER CONTAINS HIGH A MINERAL CONTENT, THE SAFETY BLOW OFF VALVES SHOULD BE SERVICED OR REPLACED AT LEAST EVERY 18 MONTHS – 2 YEARS.

Please note that we sell all types of flue pipe and fittings. We also offer a free chimney and flue pipe design and quotation service..

Not sure what you need or need some advice.. Call the experts 0161 439 1400.

, please spend more than £50

, please spend more than £50

Reviews

There are no reviews yet.