Description

Thermal Load Valve for Stoves with Back Boiler – Reduces water heat up time

Load Valve – For increasing the efficiency of a back boiler stove

A thermal load valve is a three way valve, designed to increase the efficiency of a back boiler stove by reducing the time taken to heat the water entering the back boiler.

1. Decrease the time it takes to heat hot water

2. Increase the number of radiators you can heat

3. Increase the efficiency of the stove so that you burn less fuel

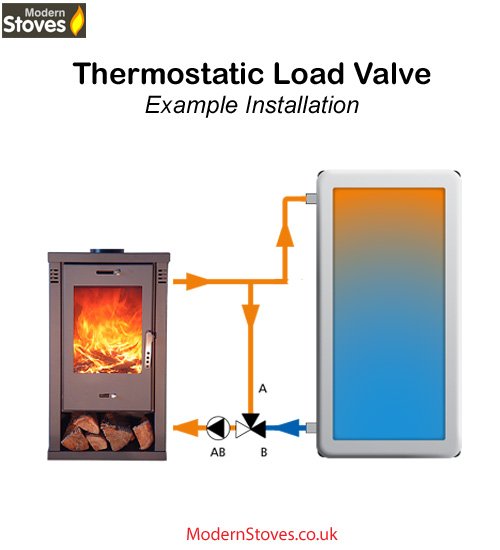

How it works:- When the fire is first lit the back boiler contains cold water, which is heated by the fire. The water is then pumped away from the back boiler and to the radiator circuit or a hot water storage tank. As the water is pumped away from the back boiler, it is followed by cooler water, which is then also heated in the back boiler.

The result is that for a period of time the back boiler is fed with cool water, which drains heat from the stove and reduces the efficiency of the appliance. It also creates a cooling effect on the inside of the stove firebox that can lead to carbon deposits lining the outerwall of the back boiler, thus insulating the water inside the back boiler from the heat and flames of the fire, which is the opposite of the desired intention of a back boiler in a stove.

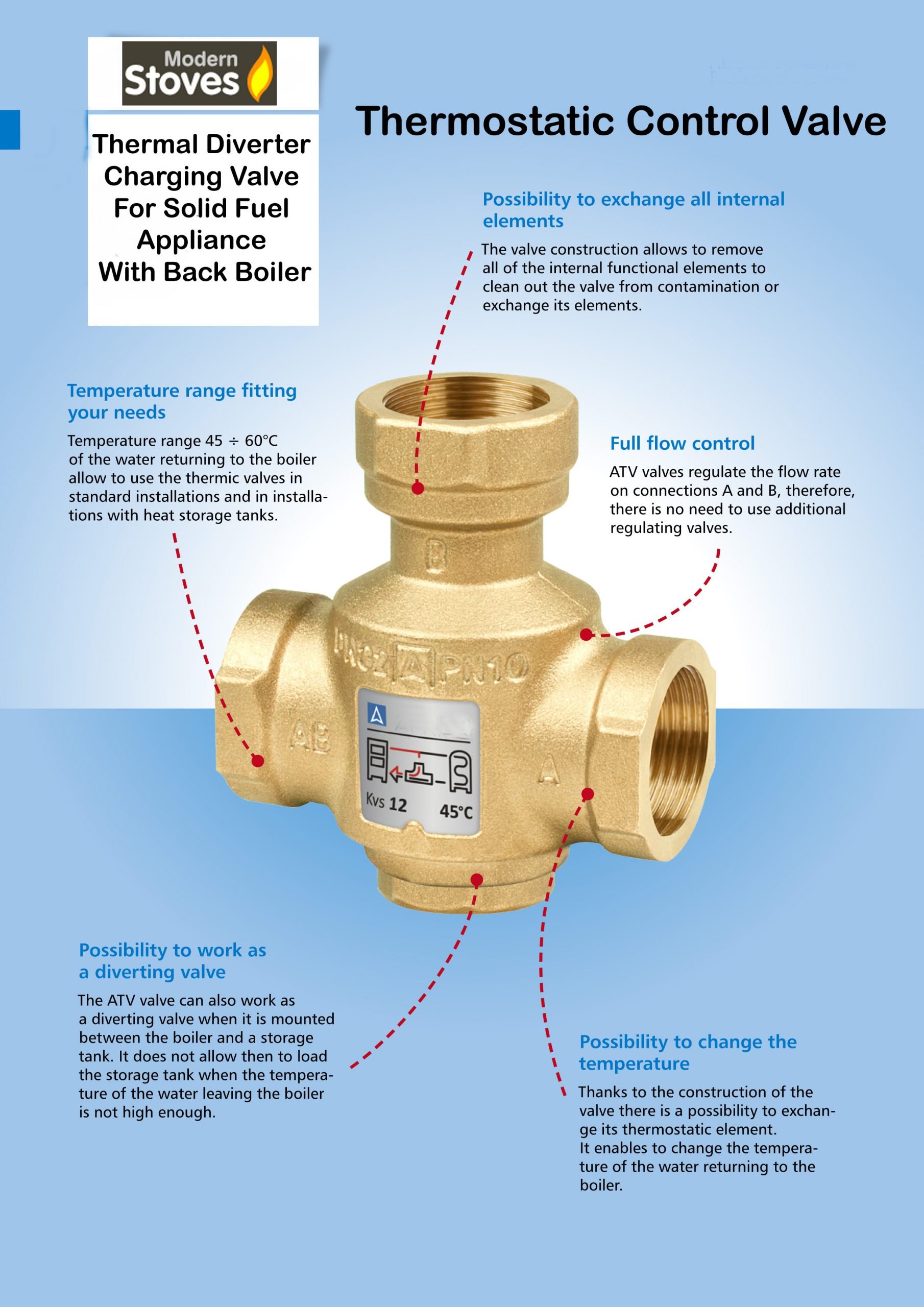

The temperature load valve is designed to be connected in line with the flow and return pipe-work from the back boiler. The load valve will monitor the temperature of the water that has been heated by the back boiler, and if the water is not at 60 degree C, it will re circulate the water to the back boiler for re-heating, thus ensuring that only water above 60 degree C is allowed to flow to the central heating or hot water storage tank. The result is the water is heated to its optimum temperature much more quickly. In addition, because the back boiler can reach its optimum temperature more quickly there is less risk of carbon deposits lining the outer wall of the back boiler.

Port A is closed until the water reaches temperature, thus leaving B open and re-circulating the water through the back boiler of the appliance. Then when the water reaches temperature, port A will open and B will close, thus allowing circulation of the water in to the central heating system or hot water tank. Port AB is the return port to the appliance. (see picture of load valve)

Phase 1. When the fire is first lit the water inside the back boiler is cold. The thermal load valve is in its closed position diverting the water back to the return flow of the back boiler to be re-heated. The valve remains closed until the water has reached the opening temperature of the thermal load valve (e.g 60C). This allows the water to reach its optimum temperature more quickly and increase the efficiency of the stove.

Phase 2. Transition Phase – When the opening temperature is reached. – When the opening temperature is reached (e.g. 60C) the circuit to the consumer is opened to allow the hot water to pass to the central heating and / or hot water tank.

Phase 3. Normal Operation (When temperature is reached). The water temperature will increase until the thermal valve is fully open, thus allowing the hot water to freely pass to the central heating and / or hot water tank, and the bypass valve is fully closed accordingly. If the water temperature subsequently drops 10C below the opening temperature (e.g. 60C) then the bypass valve will open.

For those who are familiar with the cooling system on a car engine, the process is the same in the sense that the load valve passes the water immediately back to the back boiler, for a re-heat, the process is repeated until the water reaches 60C.

The thermal load valve has three pipe connections – all of which are 1 inch BSP female. For ease of installation the thermal load valve comes complete with brass compression fittings to allow the connection to either 22mm or 15mm pipe work.

Specifications:-

Solid Brass Housing

Pre Set Thermostatic Switch 60 degrees C (+/-2)

Maximum operating temperature 110 degrees

Minimum operating temperature -20 degrees

Maximum operating pressure 10 bar

Suitable for Vented, or Un-Vented heating / hot water system

3 x Pipe Connections = 1 inch BSP, easily converted to 22mm, or 15mm.

Not sure what you need, or if you require further details.. Call 0161 439 6568 / 0161 439 1400.

Please note that we sell all types of flue pipe and fittings. We also offer a free chimney and flue pipe design and quotation service..

Please note that we sell all types of flue pipe and fittings. We also offer a free chimney and flue pipe design and quotation service..

, please spend more than £50

, please spend more than £50